3D Printer Diagrams: Your Guide to Understanding the Machine

Unlocking the mysteries of your 3D printer begins with understanding its core components. A clear diagram acts as your roadmap to successful 3D printing. This section explores the key parts and their functions. What are the most critical components to understand when interpreting a 3D printer diagram?

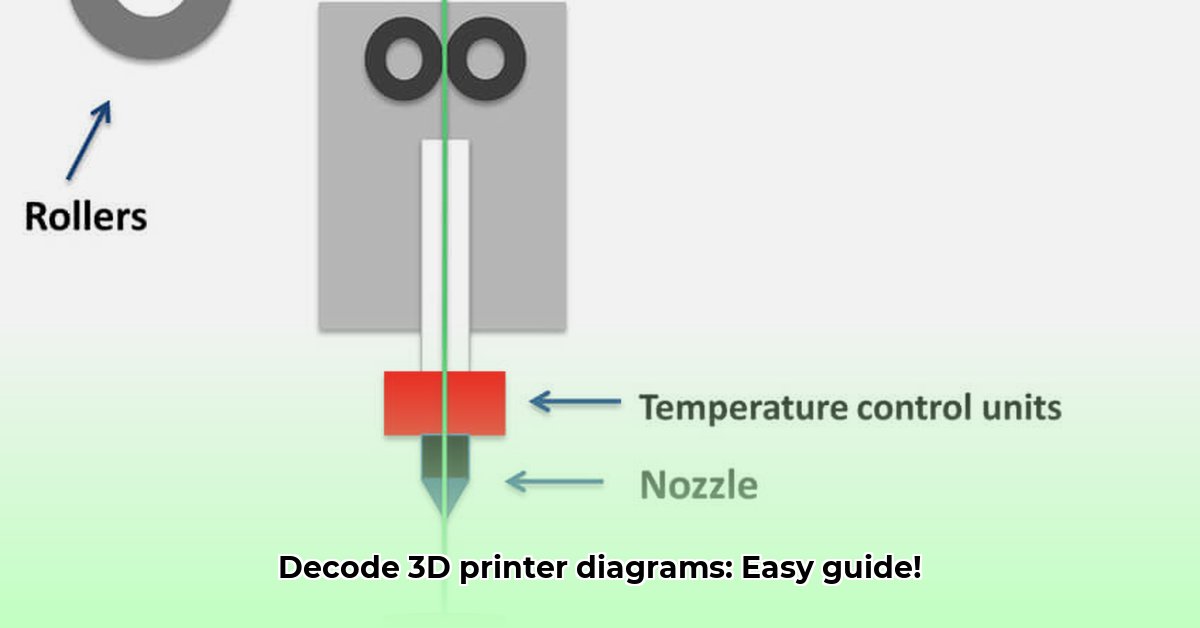

The Extruder: Melting and Extruding Filament

The extruder is the heart of the 3D printing process. It's like a precise glue gun, melting plastic filament (a thermoplastic) and forcing it through a nozzle. The nozzle's diameter influences print detail. Smaller nozzles create finer details, but at a slower speed. Larger nozzles print faster but with less detail. Most diagrams clearly show the extruder's location and connection to the print head.

There are two main extruder types:

- Direct Drive: The motor is directly attached to the nozzle for precise control. It excels with flexible filaments, but is generally heavier and may be more prone to clogging.

- Bowden: The motor is further away, connected via a tube. This lighter setup reduces inertia and clogging risk, but might slightly reduce precision, particularly with retractions (pulling filament back).

| Extruder Type | Advantages | Disadvantages |

|---|---|---|

| Direct Drive | High precision, excellent for flexible filaments | Heavier, potentially more prone to clogging |

| Bowden | Lighter, less clogging risk | Less precise, can struggle with retractions |

The Print Bed: The Foundation of Your 3D Prints

The print bed is the platform where your 3D object takes shape, layer by layer. Many beds have integrated heating elements crucial for certain plastics like ABS (acrylonitrile butadiene styrene), requiring a warm surface for proper adhesion. The bed material also impacts adhesion and ease of removal. Common materials include glass, PEI (polyetheretherketone), and BuildTak. What are the advantages and disadvantages of different print bed materials? Diagrams clearly indicate the print bed's location and heating element (if present).

The Motion System: Precise Movement for Layer-by-Layer Construction

The motion system, comprised of stepper motors, belts, and screws, moves the extruder precisely across the print bed in three dimensions (X, Y, and Z axes). The controller board directs this movement. Diagrams usually highlight the axes and their movement. Microstepping in the stepper motor drivers significantly influences print precision. Finer microstepping leads to smoother, more accurate movement. How does microstepping affect print quality?

The Control System: The 3D Printer's "Brain"

The control system, typically a controller board, serves as the printer's central nervous system. It receives instructions from your slicing software and translates them into the precise movements required by the motion system. Diagrams often show its simplified connection to other components. A reliable power supply is essential for the controller board's stable operation. Why is a stable power supply so critical for the controller board?

Deciphering 3D Printer Diagrams: A Holistic View

A comprehensive 3D printer diagram showcases the coordinated interaction of the extruder, print bed, and motion system. It illustrates the filament path and the mechanics of the printer's movements. Understanding the diagram means understanding how factors like nozzle size, bed adhesion, and filament type influence the final print. Mastering these interactions unlocks your 3D printer's full potential.

How to Choose the Best Hotend for Your 3D Printer Based on Filament Type

The hotend is a critical component, melting the filament for 3D printing. Choosing the right hotend ensures optimal print quality and longevity.

Understanding Hotend Components

The hotend is a precision heating system with several key parts:

Nozzle: The small hole where molten plastic exits. Diameter (often 0.4mm) affects resolution and speed. Materials include brass, hardened steel, and ruby (for high quality but shorter lifespan with abrasive filaments).

Heating Block: Houses the nozzle and heating element (heating cartridge).

Thermistor/Thermocouple: Temperature sensors for precise melting.

Heat Break: Prevents heat from traveling up the filament path.

Heatsink: Dissipates heat to avoid overheating.

Filament Types and Hotend Compatibility

Different filaments have different temperature requirements:

PLA: Requires lower temperatures (190-220°C). A standard hotend with a brass nozzle usually suffices.

ABS: Needs higher temperatures (220-250°C) and an enclosed chamber. All-metal hotends are recommended.

High-Temperature Filaments (PETG, Nylon, PEEK): Require hotends capable of reaching 260°C and above. All-metal hotends with hardened steel or nickel-plated copper nozzles are necessary.

Abrasive Filaments (Carbon Fiber, Metal Filled): These wear down standard nozzles quickly. Hardened steel or ruby nozzles offer better resistance.

Choosing the Best Hotend: A Step-by-Step Guide

Identify Your Primary Filament: Determine your most frequently used filament type to dictate the needed temperature range.

Set Your Budget: All-metal hotends are generally more expensive but more durable and can handle higher temperatures.

Consider Maintenance: PTFE-lined hotends are easier to clean but less suitable for high temperatures.

Check Printer Compatibility: Ensure the hotend is compatible with your 3D printer's design.

Select Nozzle Material: Choose a nozzle material suited to your filaments.

Don't Forget the Heatsink: A good heatsink prevents overheating and ensures consistent print quality.

Hotend System Comparisons: V6 vs. MK8

| Feature | V6 | MK8 |

|---|---|---|

| Temperature Range | High | High |

| Ease of Maintenance | Moderate | Moderate |

| Cost | Moderate to High | Lower to Moderate |

| Nozzle Compatibility | Specific to V6 nozzles | More widely compatible nozzles |

| Overall | More common in higher-end printers | Standard in many budget printers |

Key Takeaways

The ideal hotend depends on filament type, budget, and desired print quality. All-metal hotends offer superior high-temperature performance, while PTFE-lined hotends are easier to maintain but less suitable for high temperatures. Nozzle material significantly impacts durability. Always check your printer's compatibility before purchasing.